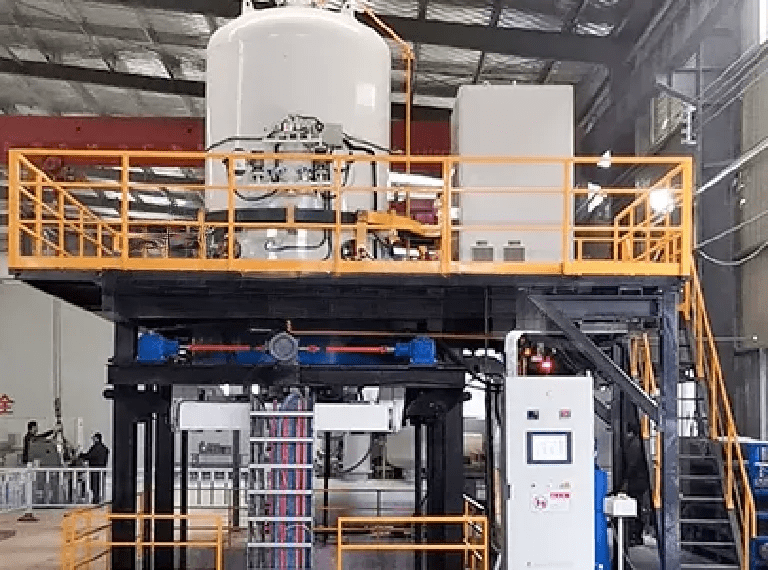

The vacuum debinding furnace is a specialized thermal processing system designed to remove organic binders from powder metallurgy components under controlled vacuum conditions. It is primarily used for the debinding of tungsten alloys, heavy metal alloys, molybdenum alloys, and cemented carbide materials. This furnace effectively eliminates binders such as polyethylene glycol (PEG), paraffin, and rubber, ensuring clean removal without residue or oxidation.

Ideal for both extrusion-formed rods and pressed parts, the vacuum debinding furnace ensures uniform heating and precise atmosphere control, minimizing deformation and contamination during the binder removal phase. The vacuum environment not only enhances binder volatilization efficiency but also protects sensitive materials from oxidation, making it highly suitable for applications in advanced ceramics, cutting tools, and high-density metal components.

Designed for high reliability and repeatable performance, this furnace is equipped with advanced temperature programming, gas inlet systems, and safety controls. It offers consistent binder removal across complex geometries, setting the foundation for successful sintering and final part integrity in high-performance industrial and technical applications.