Description

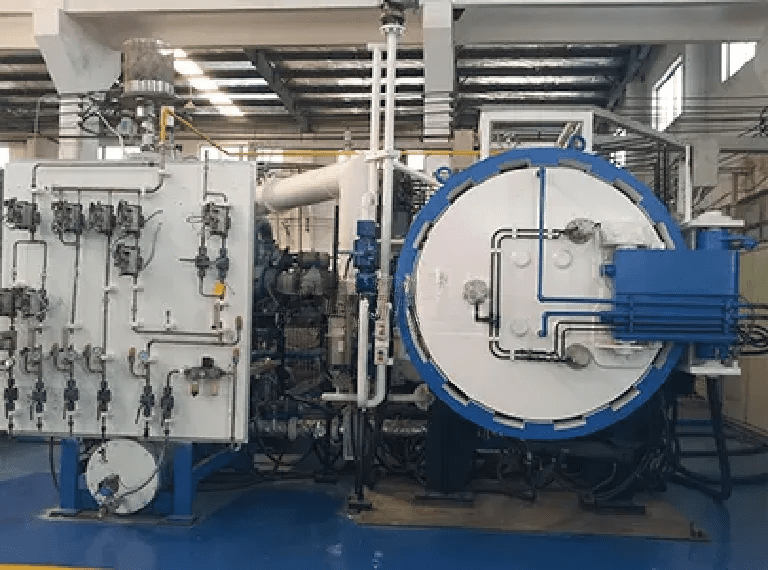

The pressure sintering furnace is an advanced high-temperature system engineered for vacuum and pressure-assisted thermal processes, including metal infiltration and high-density sintering. It is widely used for copper and tungsten alloy vacuum infiltration, as well as for vacuum sintering and pressure sintering of heavy metal alloys, molybdenum alloys, and cemented carbides.

Combining controlled atmosphere technology with isostatic or uniaxial pressure capability, this furnace ensures excellent material densification, minimal porosity, and superior mechanical properties in finished components. The pressurized environment enhances diffusion and wetting during infiltration and accelerates sintering kinetics—resulting in uniform microstructures and reduced cycle times.

Ideal for critical applications in aerospace, tooling, energy, and advanced manufacturing, the system supports various process gases and flexible temperature-pressure programming. Its robust design ensures high reliability, while precise control over process parameters makes it suitable for demanding metallurgical and ceramic production environments requiring tight dimensional tolerances and high-performance material characteristics.

Technical Details

| Description | |||

|---|---|---|---|

| Model | SMC-HTE-040408 | SMC-HTE-050513 | |

| Working Zone Size (W×H×L)(mm) | 400 × 400 × 800 | 500 × 500 × 1300 | |

| Max. Weight (kg) (not mean actual load weight) | 250 | 500 | |

| Max.temperature (°C) | 1550 | 1550 | |

| Temperature uniformity under vacuum (°C) | ±5 | ±5 | |

| Temperature uniformity under pressure (°C) | ±10 | ±10 | |

| Heating power of Pressure sinter-hip furnace (kW) | 150 | 300 | |

| Ultimate Vacuum (Pa) | 2 | 2 | |

| Pressure Increase Rate (Pa/h) | 0.67 | 0.67 | |

| Working pressure(MPa) | 1/2 | 1/2 | |

| Process gas (bar) | Ar/N2/H2 | Ar/N2/H2 |