Description

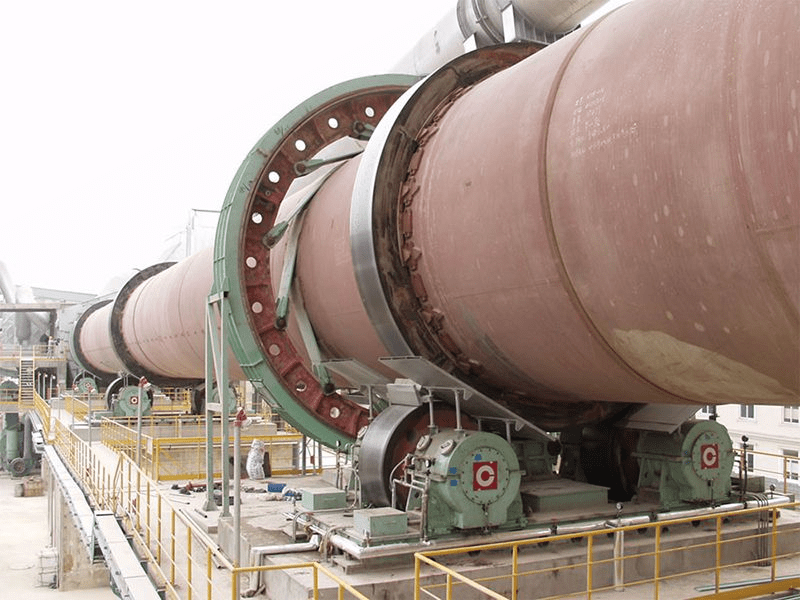

The SMC rotary kiln is a high-performance pyroprocessing system used for the calcination and sintering of a wide range of materials, including cement clinker, ferrites, and various dry powders. With production capacities ranging from 300 t/d to 10,000 t/d, our rotary kilns are engineered for versatility and durability across multiple industries such as cement manufacturing, metallurgy, and chemical processing.

SMC has successfully delivered rotary kilns for over 500 cement production lines, supporting major industrial projects across regions including Pakistan, Vietnam, the Middle East, and Africa. We have also played a key role in large-scale developments in Saudi Arabia, contributing to prominent projects throughout the country.

Our rotary kilns are trusted for their reliability, energy efficiency, and ability to meet demanding production requirements in some of the world’s most complex operating environments.

Technical Details

| Description | |||

|---|---|---|---|

| Size (m) | Φ4x60 | Φ4.3x64 | Φ4.8x74 |

| Capacity (t/d) | 2500 | 3500 | 5000 |

| Kiln Slop (%) | 4 | 4 | 4 |

| Number of Supports (pc) | 3 | 3 | 3 |

| Thruster Type | Hydraulic | Hydraulic | Hydraulic |

| Main Drive (r/m) | 0.41-4.07 | 0.4-4.0 | 0.35-4 |

| Aux Drive (r/m) | 8.2 | 7.93 | 8.52 |

| Motor Power (KW) | 315 | 400 | 630 |

| Reducer | 22.4 | 31.5 | 42.226 |