Description

Aluminum alloy ingot ADC12 is a widely used die-casting alloy made by combining pure aluminum and recycled aluminum with additional elements such as silicon (Si), copper (Cu), magnesium (Mg), and iron (Fe). These elements are added according to international standards or specific industrial requirements to enhance casting performance, mechanical strength, thermal conductivity, and corrosion resistance. ADC12 is known for its excellent fluidity, pressure tightness, and resistance to hot cracking, making it ideal for automotive parts, electronic housings, and various industrial components.

The aluminum ingot casting machine plays a crucial role in the production process by ensuring uniform shape, smooth surface finish, and consistent quality of the ingots. These machines are designed for efficiency and precision, offering hot or cold casting options based on the alloy’s application. They also support continuous casting, which improves production speed and reduces material waste.

ADC12 aluminum alloy ingots are typically produced in sizes and weights customized to customer needs, with surface treatment and packaging options such as bundled stacks secured with steel straps. The price per ton of ADC12 varies depending on global market trends, purity levels, and supplier location, but it remains one of the most cost-effective and high-performance alloys in die casting applications.

Overall, ADC12 aluminum ingots offer a reliable, durable, and economical solution for manufacturers seeking high-quality materials for structural and mechanical parts.

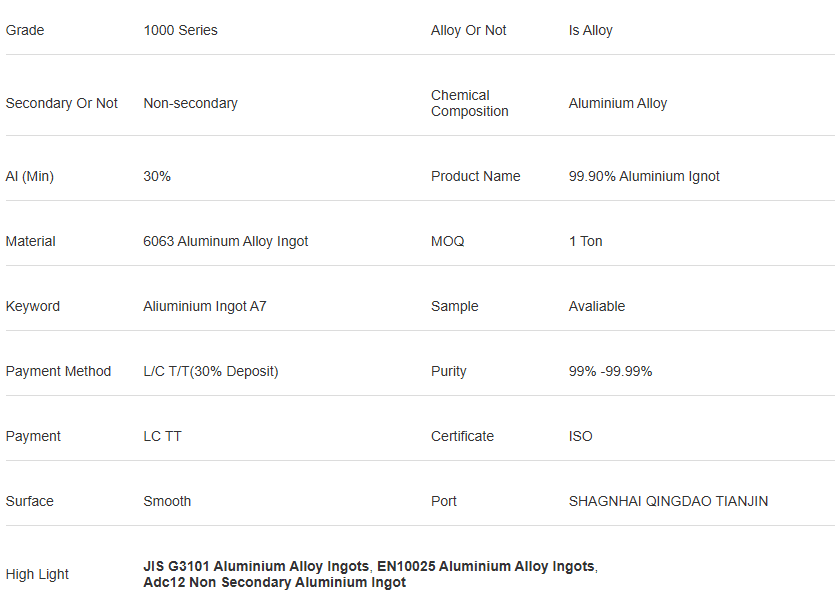

Technical Details