Description

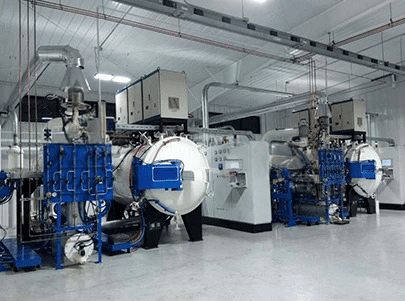

This advanced furnace is designed for high-performance processing of ceramic materials such as silicon carbide (SiC), silicon nitride (Si₃N₄), and aluminum nitride (AlN). It supports reaction sintering, low-pressure sintering, and re-crystallization of ceramic embryos and finished products. An optional degreasing system allows for integrated debinding and sintering in a single cycle, significantly improving production efficiency. Ideal for the fabrication of technical ceramics requiring precise thermal control and minimal contamination, this furnace is widely used in electronic, aerospace, and advanced industrial applications.

Technical Details

| Description | |||

|---|---|---|---|

| Model | SMC-HTE-050511 | SMC-HTE-100612 | SMC-HTE-100813 |

| Working Zone Size (W×H×L) (mm) | 500×500×1100 | 1000×600×1200 | 1000×800×1300 |

| Max. Temperature (°C) | 1500/2400 | 1500/2400 | 1500/2400 |

| Temperature Uniformity (°C) | ±5/±10 | ±5/±10 | ±5/±10 |

| Ultimate Vacuum (Pa) | 1-100 | 1-100 | 1-100 |

| Pressure Increase Rate (Pa/h) | 0.67 | 0.67 | 0.67 |