Description

Aluminium standard ingot alloy, particularly ADC12, is a widely utilized casting material known for its balanced mechanical properties and excellent castability. It is manufactured using a combination of pure aluminum and recycled aluminum, with the addition of alloying elements such as silicon (Si), copper (Cu), magnesium (Mg), and iron (Fe). These components are blended following international standards or customized requirements to enhance the alloy’s strength, thermal conductivity, corrosion resistance, and overall casting performance.

The ADC12 ingot is especially favored in the automotive and electronics industries due to its superior fluidity, dimensional stability, and resistance to hot cracking. It is commonly used for high-pressure die casting and produces components that require precise detailing and structural integrity.

Standard aluminium ingots come in customizable dimensions depending on application needs. While the casting specification provided includes sizes more typical for structural steel (e.g., H-beam specifications), aluminium ingots are usually cast in rectangular or trapezoidal blocks for ease of transport and remelting. The ingots are typically hot or cold cast and are bundled and secured with steel strips for safe handling and delivery.

Inspection is done through trusted third-party services like SGS, BV, or INTERTEK to ensure quality and compliance with international standards. The price per ton of aluminium alloy ingot ADC12 can vary based on market fluctuations, purity, and supplier, but it remains competitively priced in the global metal markets due to its recyclability and performance benefits.

Overall, ADC12 aluminium alloy ingots are a reliable and efficient choice for manufacturers seeking a durable, high-quality material for casting applications across various industries.

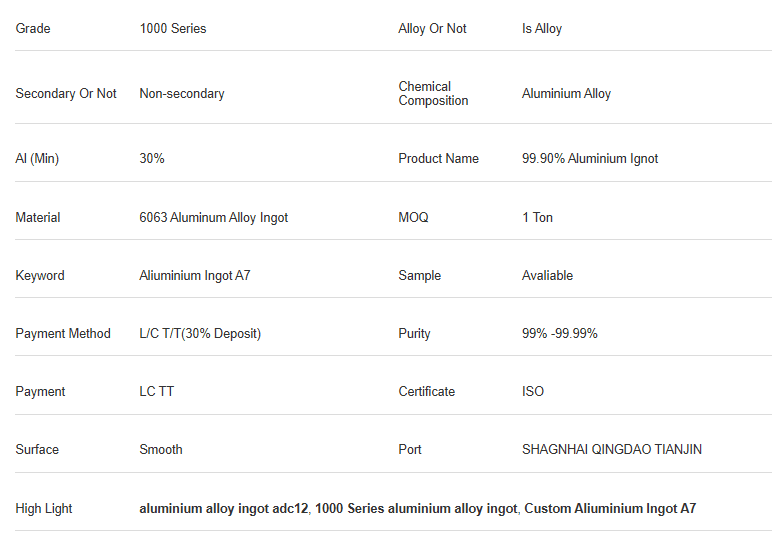

Technical Details