Description

Aluminium magnesium alloy ingots, including the widely used ADC12 grade, are engineered by blending pure and recycled aluminum with carefully controlled amounts of alloying elements such as silicon (Si), copper (Cu), magnesium (Mg), and iron (Fe). These additions significantly enhance the physical, chemical, and casting properties of pure aluminum, making the ingots ideal for high-performance industrial applications.

Magnesium, in particular, improves the strength-to-weight ratio, corrosion resistance, and hardness of the alloy, making it highly suitable for automotive components, aerospace parts, and electronic housings. ADC12 alloy, known for its excellent castability, thermal conductivity, and dimensional stability, is often the preferred choice for die casting processes.

These ingots are compatible with modern aluminium ingot casting machines, which provide precision shaping and consistency in production. The casting process ensures uniform quality, clean surfaces, and optimal mechanical characteristics, making them ready for melting and further manufacturing.

The price per ton of aluminium alloy ingot ADC12 varies based on factors such as raw material costs, purity, market demand, and shipping origin. However, due to its recyclability and broad industrial use, ADC12 remains cost-effective and in high demand globally.

In summary, aluminium magnesium alloy ingots, particularly ADC12, offer a powerful combination of strength, durability, and castability, making them essential in a wide range of manufacturing industries, while also supporting sustainable production practices through the use of recycled materials.

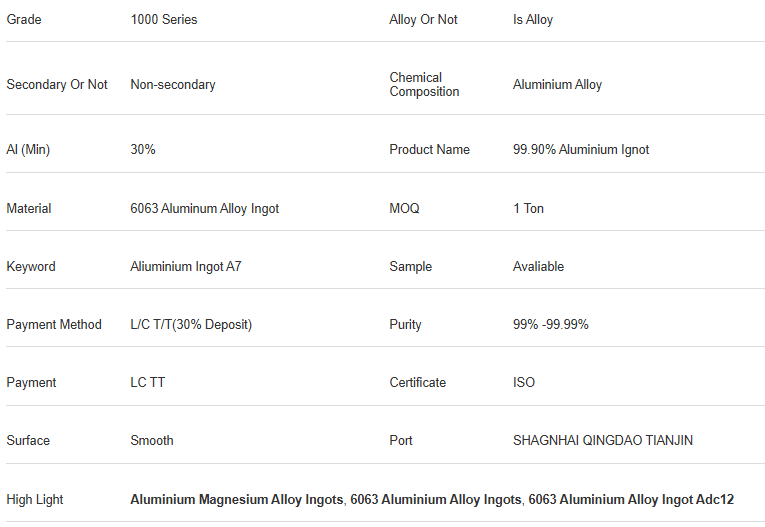

Technical Details