Description

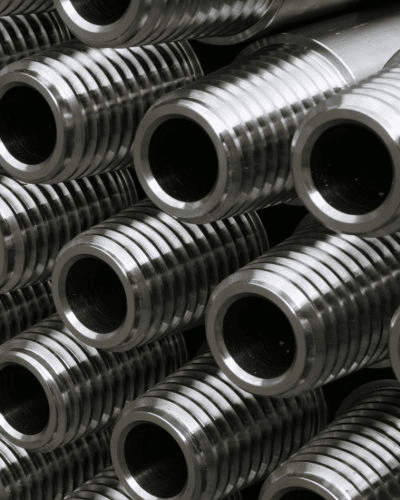

SMC drill rods are essential components in any core drilling system, serving as the transmission link between the drill rig and the cutting tool. These hollow rods deliver both rotational force and axial thrust to the core bit while simultaneously allowing the circulation of drilling fluid through their interior. This fluid cools the bit and helps transport cuttings to the surface.

Each rod features a male thread on one end and a female thread on the other, enabling a secure and continuous connection of multiple rods to reach greater depths. At the end of the rod string, the final connection is made to the core barrel, completing the drilling assembly. Built for strength, durability, and precise threading, SMC rods ensure efficient and safe drilling operations.

Casing pipes from SMC are used to support and protect the walls of an already-drilled borehole, not for the drilling process itself. Installed after drilling, casings prevent borehole collapse, isolate unstable zones, and ensure the integrity of the hole during sampling or further drilling operations. They are always inserted into a borehole with a diameter larger than the casing itself.

SMC offers various casing types to match different drilling standards and conditions, including:

Metric Casings – Standardized to fit metric drilling systems.

W and WT Casings – Widely used in geotechnical and exploration drilling for their compatibility with common core barrel sizes and accessories.

With precise manufacturing and durable materials, SMC casings provide reliable borehole stability and long-term performance in a range of drilling environments.