Description

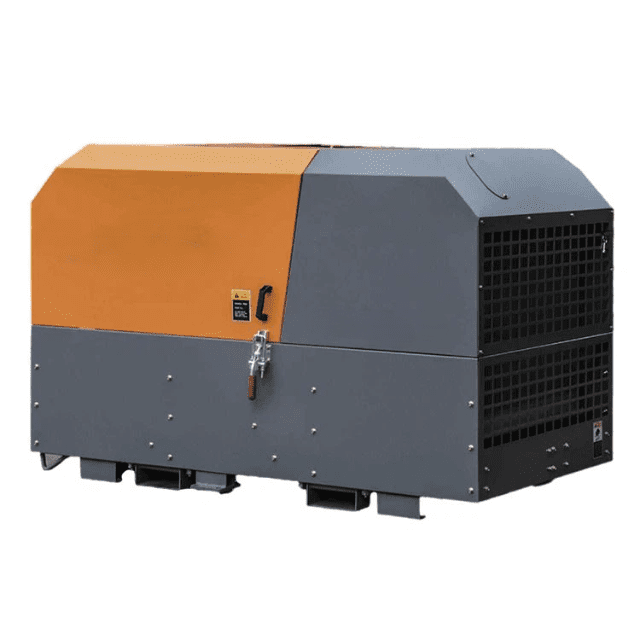

SMC Diesel Stationary Screw Air Compressors are engineered for reliable performance across a wide range of demanding industries. From construction, mining, and oil drilling to ship repair and geothermal projects, these compressors are used wherever compressed air is essential. Their adaptability makes them a vital tool across countless applications.

Air is the preferred compression medium because it is safe, clean, readily available, and easy to handle. In addition to air, SMC compressors can also handle inert gases such as dry nitrogen and carbon dioxide, which are chemically stable and environmentally safe.

Compressed air systems are structured in stages—each compression cycle followed by cooling is known as a stage. In high-power compressors, multiple stages can form a section. While terminology may vary by region, the function remains the same: efficient and dependable compression for industrial needs.

Technical Details

| Description | |||

|---|---|---|---|

| Model | SPDB175S | ||

| China II Engine | Xichai/ 41 kW/55 HP | ||

| Diesel tank volume | 65L | ||

| Air End | Single Stage Compression | ||

| Dimensions (L×W×H)mm | 1,800×1,040×1,1,300 mm | ||

| Rated FAD | 5 m³/min | ||

| Rated Pressure | 7 bar | ||

| Weight | 750kg | ||

| Rated exhaust pressure | 0.7MPa | ||

| Exhaust oil content | ≤ 3 PPM | ||

| Exhaust temperature | 80℃-110℃ | ||

| Voltage | 380V | ||

| Frequency | 50Hz | ||

| Noise level (dB) | ≤85dB | ||

| Minimum reservoir pressure | 4.5bar | ||

| Maximum reservoir pressure (compressor unloading) | 7bar | ||

| Minimum starting temperature | -10℃ | ||

| Maximum ambient temperature | 45℃ |