Description

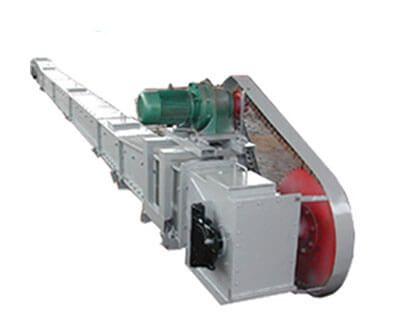

The MS En Masse Conveyor, also known as a buried scraper conveyor, is a continuous conveying solution designed to efficiently transport powdered, granular, or small block materials within a sealed rectangular casing. Powered by a robust scraper chain fully immersed in the material flow, this conveyor ensures minimal dust emissions and reduced material degradation—making it ideal for use in cement plants, metallurgy, machinery, grain handling, and light industries.

Whether handling standard bulk material or thermally sensitive and specialty-grade substances, AGICO’s en masse conveyors offer reliable and versatile performance in diverse applications.

Product Advantages:

Compact & efficient design: Small footprint with high conveying capacity

Fully enclosed casing: Prevents dust escape and environmental pollution

Modular setup: Supports single conveyor systems or multi-unit series configurations

Easy installation & maintenance: Simplified layout reduces downtime

Customizable models: Available in general, thermal, grain, and cement-specific types

As a trusted manufacturer of cement equipment, AGICO provides both standard and custom-sized en masse conveyors tailored to meet the specific demands of your material handling process.

Technical Details

| Description | |||

|---|---|---|---|

| Model | MS16 | MS20 | MS25 |

| Material Bulk Density(t/m³) | 0.2-1.8 | 0.2-1.8 | 0.2-1.8 |

| Capacity(m³/h) | 15-30 | 23-46 | 36-72 |

| Maximum Conveying Length(m) | 40 | 40 | 40 |

| Dip Angle | 0-15° | 0-15° | 0-15° |

| Scraper Space(mm) | 200 | 200 | 200 |

| Chain Pitch(mm) | 100 | 125 | 160 |

| Roller Diameter(mm) | 28 | 28 | 28 |

| Chain Model | TG100 | TG100 | TG100 |