Description

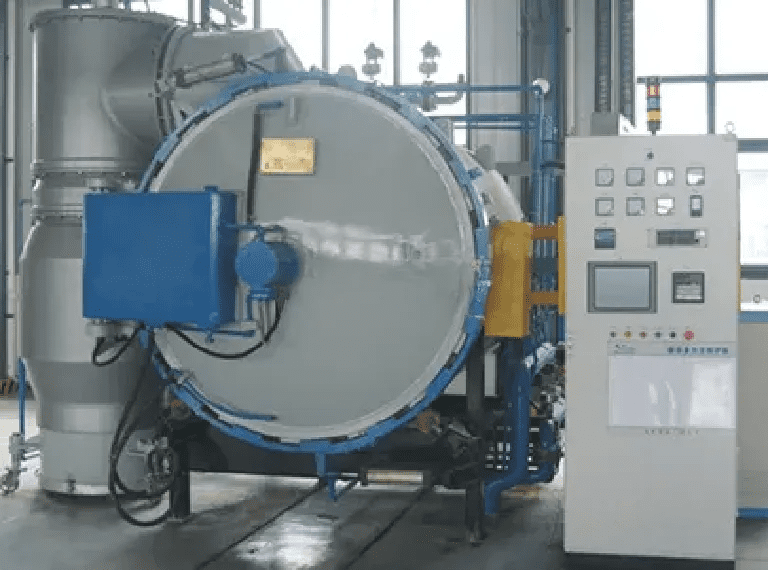

The high vacuum sintering furnace is a precision-engineered thermal processing system designed for sintering advanced materials under ultra-clean, high-vacuum conditions. It is primarily used for the sintering of tungsten alloys, magnetic materials, heavy metal alloys, molybdenum alloys, cemented carbides, and for blackening treatments of zirconium oxide (ZrO₂). By operating in a high-vacuum environment, this furnace ensures minimal contamination, improved material purity, and enhanced microstructural consistency.

Equipped with advanced temperature control and uniform heat distribution, the system supports sintering at elevated temperatures with excellent repeatability. This makes it ideal for producing high-density, high-performance components used in aerospace, electronics, medical, and industrial tooling applications.

The furnace also supports customizable process parameters and multiple atmosphere configurations, allowing manufacturers to tailor the sintering cycle to meet specific material requirements. Its robust insulation, energy-efficient heating elements, and integrated safety features make it a reliable and cost-effective solution for critical applications requiring precision metallurgy and high-purity results.

Technical Details

| Description | |||

|---|---|---|---|

| SpecModel | SMC-HTE-020203 | SMC-HTE-040412 | SMC-HTE-060612 |

| Working Zone Size (W×H×L)(mm) | 200 × 200 × 300 | 400 × 400 × 1200 | 600 × 600 × 1200 |

| Max.Weight (kg) (not mean actual load weight) | 30 | 300 | 600 |

| Max.temperature of vacuum sintering furnace (°C) | 1550 | 1550 | 1550 |

| Temperature Uniformity (°C) | ±3 | ±3 | ±5 |

| Heating Power (kW) | 45 | 90 | 180 |

| Ultimate Vacuum (Pa) | 2×10-3 | 2×10-3 | 2×10-3 |

| Pressure Increase Rate (Pa/h) | 0.67 | 0.67 | 0.67 |

| Process gas | Ar/N2 | Ar/N2 | Ar/N2 |