Description

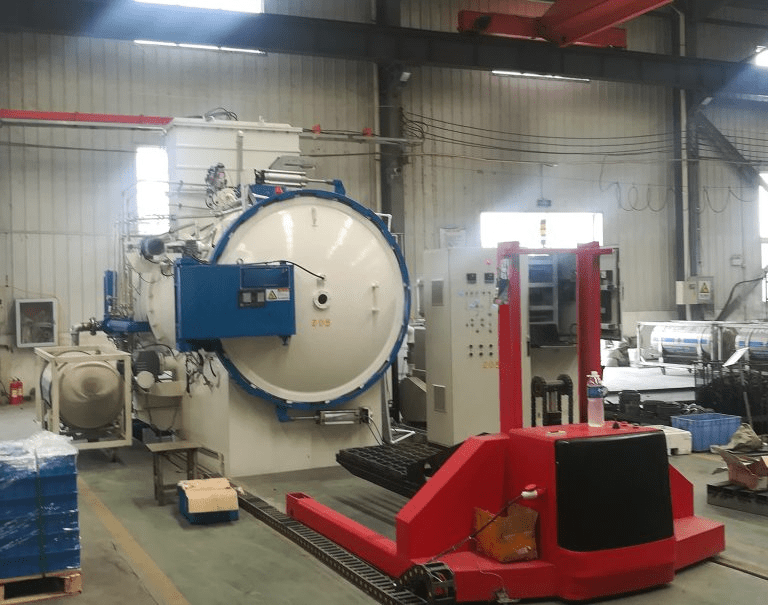

The horizontal vacuum carburizing furnace is a specialized heat treatment solution designed for high-precision carburizing and quenching of various steels under controlled vacuum conditions. It is ideal for processing structural steels, high-alloy carburizing steels, stainless steels, tool steels, and die steels. By operating in a low-pressure environment, this furnace enables uniform carbon diffusion into metal surfaces without oxidation or surface decarburization, resulting in enhanced hardness, wear resistance, and fatigue strength.

This system is commonly used for the treatment of gear components, precision sleeves, shafts, pump plungers, injector nozzles, and other high-performance mechanical parts that demand consistent surface properties and dimensional stability. The furnace supports a range of thermal processes—including carburizing, quenching, and annealing—within a single, automated cycle. It offers precise temperature and atmosphere control through advanced PID programming, ensuring repeatable results across complex geometries and part configurations.

With its horizontal design and optimized heat zone, the furnace facilitates easy loading and efficient batch processing. Its rapid heating and quenching capabilities significantly reduce processing times while minimizing distortion. The result is a reliable, high-throughput system ideal for industries such as automotive, aerospace, tool manufacturing, and precision engineering—where component quality, performance, and consistency are critical.

Technical Details

| Description | |||

|---|---|---|---|

| Model | SMC-HTE-335D | SMC-HTE-446D | SMC-HTE-557D |

| Effective hot zone size W×H×L (mm) | 300 × 300 × 500 | 400 × 400 × 600 | 500 × 500 × 700 |

| Loading capacity(kg) | 75 | 250 | 400 |

| Heating Power (kW) | 48 | 75 | 90 |

| Max.Temperature(°C) | 1150/1350 | 1150/1350 | 1150/1350 |

| Temperature Uniformity (°C) | ±5 | ±5 | ±5 |

| Vacuum degree (Pa) | 4× 10⁻¹ | 4× 10⁻¹ | 4× 10⁻¹ |

| Pressure Increase Rate (Pa/h | ≤0.26 | ≤0.26 | ≤0.26 |

| ≤0.65 | ≤0.65 | ≤0.65 | |

| Carburizing medium | C2H2+N2 | C2H2+N2 | C2H2+N2 |

| Carburizing medium pressure (mbar) | 5-20 | 5-20 | 5-20 |

| Controlling way | Multi-pulse | Multi-pulse | Multi-pulse |

| Transportation time (S) | ≤15 | ≤20 | ≤25 |

| Quenching medium | Oil/gas | Oil/gas | Oil/gas |