Description

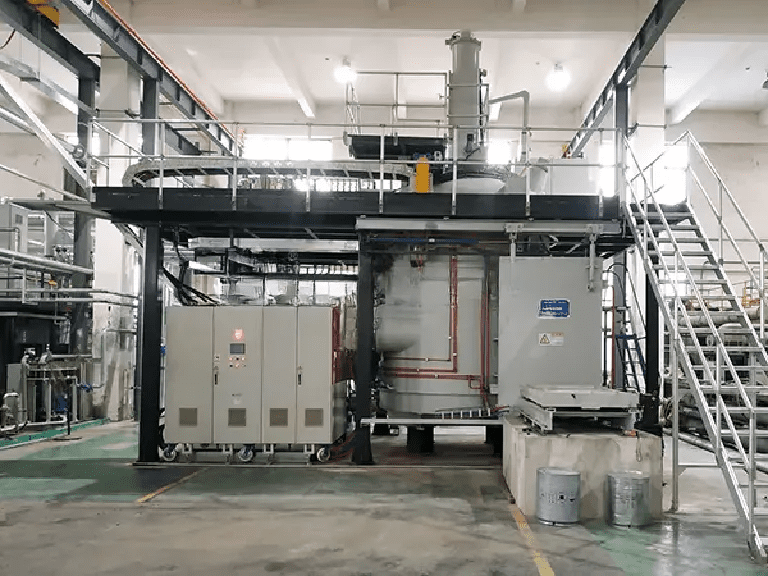

The vacuum gas quenching furnace is a high-performance heat treatment solution designed for the precise hardening of materials such as tool steels, die steels, high-speed steels, and other alloy steels. It delivers uniform quenching results through high-pressure inert gas cooling, all within a clean vacuum environment. Unlike traditional quenching methods, this furnace accommodates components of various shapes and sizes without the need for special fixturing, making it highly versatile for a wide range of industrial applications.

Engineered to minimize thermal distortion, this system ensures excellent dimensional stability, even in precision-engineered parts. The high-pressure gas quenching process provides rapid, uniform cooling, enhancing hardness and mechanical performance while preserving part integrity. This makes it ideal for hardening complex molds, dies, cutting tools, precision gears, and other critical components used in aerospace, automotive, tooling, and manufacturing industries.

With controlled vacuum levels and advanced temperature management, the furnace ensures oxide-free surfaces and consistent metallurgical results. Its automated operation, low-maintenance design, and repeatable quenching cycles make it a reliable choice for manufacturers seeking to improve product quality, reduce post-processing, and optimize thermal treatment efficiency.

Technical Details

| Description | |||

|---|---|---|---|

| Model | SMC-HTE-224S | SMC-HTE-335S | SMC-HTE-446S |

| Effective hot zone size W×H×L (mm) | 200 × 200 × 400 | 300 × 300 × 500 | 400 × 400 × 600 |

| Loading capacity(kg) | 50 | 75 | 250 |

| Heating Power (kW) | 36 | 48 | 75 |

| Max.Temperature(°C) | 1150 | 1150 | 1150 |

| 1350 | 1350 | 1350 | |

| Temperature Uniformity (°C) | ±5 | ±5 | ±5 |

| Vacuum degree (Pa) | 4 × 10⁻¹ | 4 × 10⁻¹ | 4 × 10⁻¹ |

| 4 × 10⁻³/6 ×10⁻⁴ | 4 × 10⁻³/6 ×10⁻⁴ | 4 × 10⁻³/6 ×10⁻⁴ | |

| Pressure Increase Rate (Pa/h) | ≤0.26 | ≤0.26 | ≤0.26 |

| ≤0.65 | ≤0.65 | ≤0.65 | |

| Gas quenching pressure (bar) | 6/10/15/20/40/60 | 6/10/15/20/40/60 | 6/10/15/20/40/60 |