Description

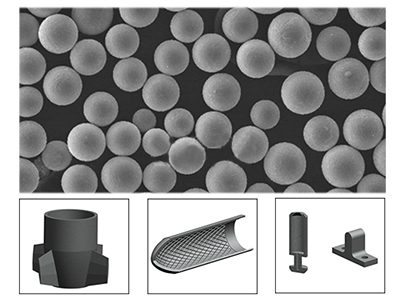

SMC-HTE SS Powder – High-Purity Spherical Metal Powder

The SMC-HTE SS Powder is produced using the PREP method, which utilizes a metal or alloy as the consumable electrode. Under centrifugal force, this method effectively creates spherical metal powder. It eliminates the formation of slugs and avoids contact with refractory materials, ensuring that non-metallic impurities are removed. The result is a high-purity, spherical powder ideal for various advanced applications.

Technical Details

| Description | |||

|---|---|---|---|

| Grade | 304 | 316L | S301 |

| Main Element | Mn:≤2.00 Ni:8.0-12.0 Cr:8.0-20.0 | Cr:16.00-18.00 Ni:10.0-14.0 Mo:2.0-3.0 Mn:≤2.00 Fe:Bal | Ni:6.0-8.0 Cr:16.0-18.0 Fe:Bal |

| Impurity Element | C :≤0.08 Si:≤1.00 P :≤0.045 S :≤0.03 O :≤0.05 | Si:≤1.00 P :≤0.04 S :≤0.03 C :≤0.03 O :≤0.05 | C :0.15 Si:1.0 Mn:2.0 P :0.045 S :0.03 N :0.1 O :≤0.05 |

| National Standard | GB/T 1173-2013 | GB/T 1220-2007 | GB/T 1220-2007 |

| USA Standard | Nil | F1527 | Nil |

| Particle Size Distribution | 15-45μm (15-53μm) (53-120μm) (53-150μm) | 15-45μm (15-53μm) (53-120μm) (53-150μm) | 15-45μm (15-53μm) (53-120μm) (53-150μm) |