Description

Aluminum alloy ingots, including the high-purity A7 specification, are produced using a blend of pure aluminum and recycled aluminum, with the addition of alloying elements such as silicon (Si), copper (Cu), magnesium (Mg), and iron (Fe). These elements are incorporated based on international standards or specific customer requirements to enhance the casting characteristics and mechanical properties of the base aluminum. The ingots are processed using advanced aluminum ingot casting machines, ensuring consistent quality, shape precision, and production efficiency. These machines support hot rolled, cold rolled, or welded techniques depending on the application requirements.

The A7 grade aluminum ingot boasts a minimum aluminum purity of 99.97%, making it ideal for industries that demand high-quality raw materials, including construction, automotive, and electronics manufacturing. Specifications for size range from a web width of 100–900mm, flange width of 100–300mm, and thicknesses from 5–30mm, with standard lengths of 6m, 9m, or 12m—or customized as per client needs. The material grades comply with standards such as JIS G3101, EN10025, ASTM A36, A572, and A992, covering common materials like Q235B, Q345B, SS400, SS540, and A36.

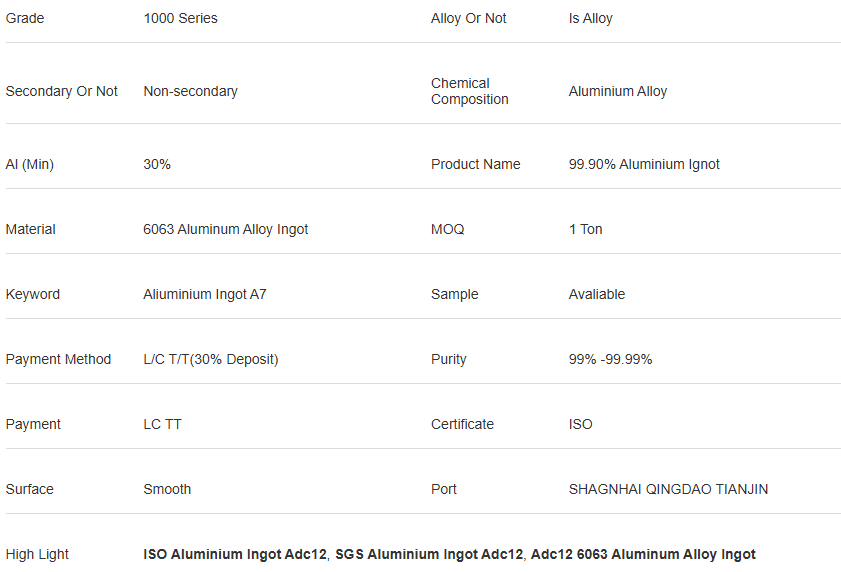

Aluminum alloy ingot ADC12, widely used in die casting, is priced per ton based on market demand and alloy purity. These ingots are typically packaged in bundles and fastened with steel strips for secure transportation and can be inspected by third-party services like SGS, BV, or INTERTEK to ensure compliance and quality assurance.

Technical Details