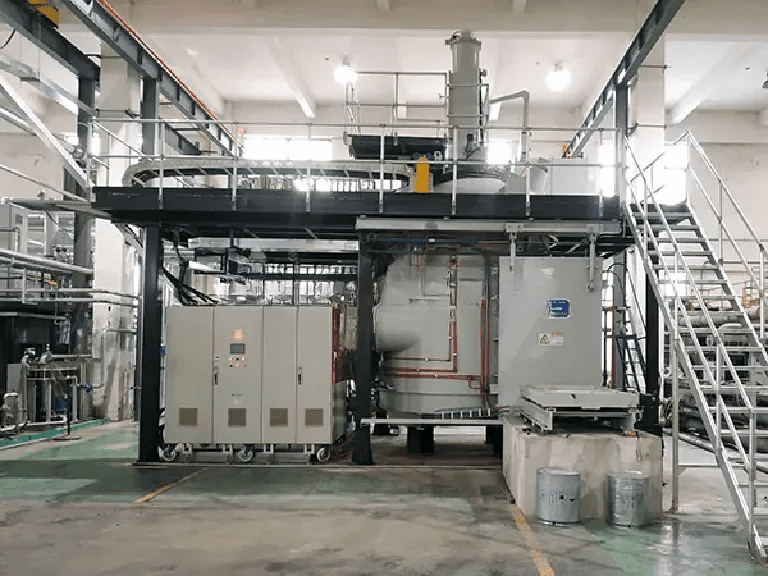

The vacuum induction melting furnace is an advanced metallurgical system designed for melting and refining a wide range of materials under vacuum or inert gas atmosphere. Using the principle of electromagnetic induction, it generates eddy currents within the charge material to produce clean, controlled heat. This non-contact heating method enables precise temperature control and uniform melting, making it ideal for processing ordinary steels, special alloys, high-temperature superalloys, precision alloys, non-ferrous metals, rare earth magnetic materials, and industrial-grade silicon.

By operating under vacuum or a protective gas environment, the furnace effectively eliminates oxidation and contamination, ensuring high purity and superior material properties. It is widely used in the production of high-performance components where chemical consistency and metallurgical integrity are critical, such as in aerospace, electronics, energy, and precision engineering industries.

Capable of melting both ferrous and non-ferrous metals, the system offers excellent flexibility in batch sizes and alloy compositions. Its advanced control system allows for precise adjustment of melting parameters, real-time monitoring, and repeatable results. With low energy loss, minimal emissions, and high thermal efficiency, the vacuum induction melting furnace is a reliable solution for modern metallurgical operations that demand quality, purity, and process control.