Description

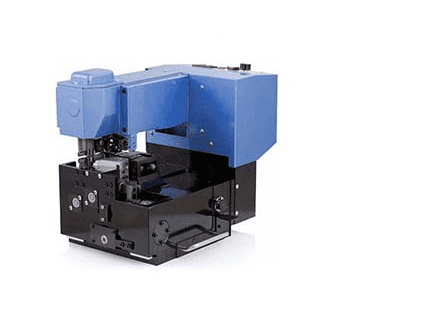

The Advanced Knotting Machine is engineered with world-class technology to support a wide range of yarn types and weaving mills. With its maximum speed of 600 knots per minute, it offers outstanding efficiency, drastically reducing loom downtime and improving overall productivity. Designed to adapt to different weaving environments, this machine provides exceptional versatility and can be mounted either on a loom frame or a mobile trolley based on customer preference.

Key Features:

High Speed and Efficiency: Capable of tying up to 600 knots per minute, significantly increasing operational speed and reducing loom downtime.

Versatility: The machine can be easily mounted on a loom frame or used on a mobile trolley, offering adaptability based on your production setup.

User-Friendly Interface: Simplifies operation, enhancing operational continuity and minimizing manual intervention during warp changes.

Enhanced Yarn Splitting: Supports high-speed yarn splitting at a running speed of 400 rpm, achieving 50%–100% faster splitting performance compared to traditional systems, improving overall throughput.

Adjustable Split Ratios: Allows for flexible adjustment between 1:1 or 2:2 split ratios to meet specific yarn processing needs.

Precision Warp Tension Adjustment: Features a single-handle warp tension adjustment system for easy, precise control, improving the consistency of the final product.

Efficient Warp Separation: A special warp separation mechanism ensures precise tell operations, enhancing yarn quality.

Stable, Adjustable Performance: The cam-driven main part ensures stable and adjustable performance for reliable results.

Quick-Exchange Mechanism: The splitting needle mechanism allows for quick exchanges, minimizing downtime and enhancing convenience.

Benefits:

Improved Productivity: The high-speed knotting and splitting capabilities ensure faster production cycles, leading to higher throughput and less operational interruption.

Ease of Maintenance: The quick-exchange components and user-friendly setup ensure easy maintenance, reducing the time and effort required for upkeep.

Versatility for Various Yarns: Capable of handling almost all types of yarn, this machine is a valuable addition to any weaving mill.

Precision and Control: The precise warp tension and split ratio adjustments enable superior control over the weaving process, ensuring high-quality end products.

Technical Details

| Description | |||

|---|---|---|---|

| MODEL | SMC-TE-WKM-I | SMC-TE-WKM-II | SMC-TE-WKM-III |

| Warp type and material | Cotton yarn,wool yarn, silk yarn, blended yarn, long fiber yarn, singer fiber yarn, industrial yarn | Nil | Nil |

| Warp Count Range / Yarn Thickness Range | 100Ne~0.7Ne,10Den-1500Den | Nil | 100s-1s 10d-4000d |

| Warp Speed / Running Speed | Up to 600 per minute | 7-400 RPM CVT | Up to 600 per minute |

| Touching screen | Convenient and quick menu inquiry and the setting as well as the procedure change, but also may touch the screen to start and stop the machine | Nil | Nil |

| Effective width | 1m-3.5m,can be customized as per needs | 75’’ 85’’ 95’’ 105’’ 110’’ 130’’ 140’’ | 1m,1.8m,2m,2.3m,2.5m,3m,3.5m,3.8m(customized as per requirement) |

| Motor | New version brushless motor DC36V 180W | DC100-120V,50W | New Type brushless motor DC36V 180W |

| Adapted to Yarn Type | Nil | Special for long fiber(chemical fiber, synthetic fiber, spun silk),special for short fiber(cotton yarn, blended yarn wool) | Cotton,Wool,Silk,Chemical Fiber,Glass Fiber |

| Number of strands | Nil | Three | Nil |

| Adapt to the Condition of Meridian Formation | Nil | Nil | The antithesis of no-twist fabric and no twist warp beam The antithesis of non-twisted fabric and hinged warp beam The coupling of a hinged fabric to a non-hinged beam The pairing of a hinged fabric width a hinged beam |